Prototype production, design, and sales of wire harnesses. From the Port of Shanghai to destinations throughout Asia.

Our Services

Equipment

Wire harness production equipment

Cutting, crimping, and soldering process

A fully automatic cutting, crimping, and soldering machine will automatically cut and strip wires, crimp terminals, and solder ends.

When crimping terminals, the crimping force applied to all products is measured using a crimp force monitor, to capture unusual changes in force and detect defective products.

Quality inspection process

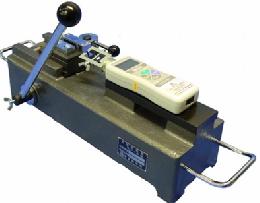

Fixing strength test

|

A tensile test is performed to measure the fixing strength of crimped terminals.

Cross-section examination of terminals

|

Crimped terminals are cut cross-sectionally for quality examination of the terminal.

In-process inspection process

|

The caulking state of crimped terminals is inspected based on a terminal specification sheet.

Wire processing

Sub-assembly

|

Terminals are fitted into connectors to make a sub-assembly.

Assembly

|

Arranging

Sub-assemblies are arranged on a jig board.

|

Sheathing

The arranged wires are wrapped in tape, and attachments such as those needed to attach the wire harness to vehicles are installed.

Inspection process

|

Conduction inspection

The wiring and disconnection of wires are electronically tested using a circuit checker.

|

Visual inspection

The assembled wire harness is checked against a product sample. Important parts are subjected to image inspection and the results are recorded.

Links

Click here for further information or quotations.